Crusher Rotor

CRUSHER ROTOR

Crusher machine has been widely used in mining, metallurgy, highway, building materials and other industries. Crusher rotor is a part of the crusher machine and its working performance directly affects the productivity of the crusher machine.

STRUCTURE OF CRUSHER ROTOR

Hammer crusher rotor consists of shell, crusher rotor, strike plate, hammer head, bracket, liner and so on.

The crusher rotor of the hammer crusher consists of a main shaft, a hammer disc, a pin shaft, and a hammer head. The main shaft is the most important part of the hammer crusher to support the rotor. The weight and impact force of the crusher rotor and the hammer head are all borne by it. Therefore, the material of the main shaft needs to have high toughness and strength. The material of the main shaft is made of high-quality alloys. steel. According to an essay, the rotor peripheral speed of the hammer crusher is currently 18-70m/s.

1. Main shaft

The main shaft is of circular design, the hammer head and the hammer frame are driven to rotate by the rotation of the main shaft. The main function of the main shaft is to bear the weight and impact force from the rotor and the hammer head and ensure stable rotation, which means higher requirements for the material of the main shaft. For some machines, the spindle used for hammer crushing needs to be forged with 35# silicon-manganese-molybdenum-vanadium steel with higher strength and toughness, which is more durable.

2. Hammer frame

The hammer frame is connected to the main shaft and the hammer head, and is not used for crushing materials. However, the hammer frame will still be worn by the impact and friction of the ore during operation. Therefore, the hammer frame is generally selected from high wear-resistant materials. There will be 12 pin holes on the hammer frame, which are divided into two groups. Generally speaking, the newly replaced hammer head is hung on the inner shaft hole of the hammer crusher, and the worn hammer head is hung on the outer shaft hole, so that the new hammer head can be replaced after the hammer head is worn out to saving maintenance costs.

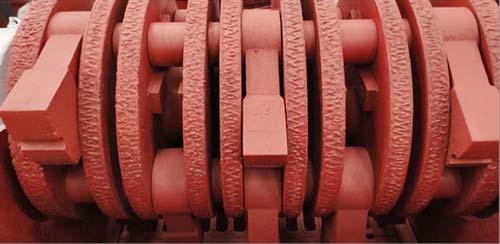

3. Hammer

The hammer head is the part that mainly contacts the ore. The material is crushed by the hammer head's striking and grinding. Therefore, the size, material and shape of the hammer head will affect the crushing effect and crushing efficiency. The higher the weight of the hammer head, the greater the kinetic energy generated during high-speed rotation, and the higher the crushing strength, but the excessive weight may also cause the problem of slow rotation, so the weight is moderate; in addition, the material of the hammer head It is also very important. Generally, high manganese steel casting hammer head can be selected and heat treated, which can make the hammer head have higher wear resistance and impact resistance, and have a longer service life. If it is found to be worn for a long time, it needs to be replaced in time to avoid the broken effect.

4. Flywheel

The flywheel will store a certain kinetic energy during the rotor operation to ensure the rotor can run smoothly, and can reduce the power consumption of the crusher and ensure the crushing effect.

The crusher rotor of the hammer crusher is the part that drives the hammer crusher to work. The quality of the performance will directly affect the production capacity and crushing effect of the hammer crusher. It is necessary to ensure that there is no wear and tear, and the overall operation is stable. Therefore, daily maintenance should also be done during use, and it should be replaced in time after wear.

ADVANTAGES OF AGICO CEMENT'S CRUSHER ROTOR

1. The retaining ring technology prolongs the service life of the rotor. Under the impact of stone, the edge of the rotor and hammer plate of the crusher is easily worn out, and the rotor has to be replaced after wear. In response to this situation, AGICO Cement introduced the retainer technology, which greatly improved the life of the rotor, unscrew the bolt to replace the retainer so that the replacement the crusher rotor is uneccessary.

2. The diameter of the hammer disc is increased, and the hammer head can rotate 360 degrees, which reduces the direct impact of the hammer head with the spacer sleeve during the turning process of the hammer head, thus solving the problem that the spacer sleeve of the traditional hammer crusher is easily broken or loosened by the hammer head, and the hammer head falls off and the problem that the hammer shaft is easy to break.

3. The chromium and manganese composite casting of the hammer head improves the impact resistance of the hammer handle and the performance of the hammer head.

4. The tungsten-titanium alloy full-armor protection design on the rotor surface of the crusher reduces the stress concentration of the hammer disc and the end hammer disc, enhances its strength, effectively prevents the problem of breakage, and can effectively prevent the crusher from being stuck and double the life of the crusher rotor.

5. Improve the output of the crusher, adopt the variable rotational inertia design, effectively improve the crushing efficiency, increase the output of the crusher, and reduce the fineness by 20~30%.

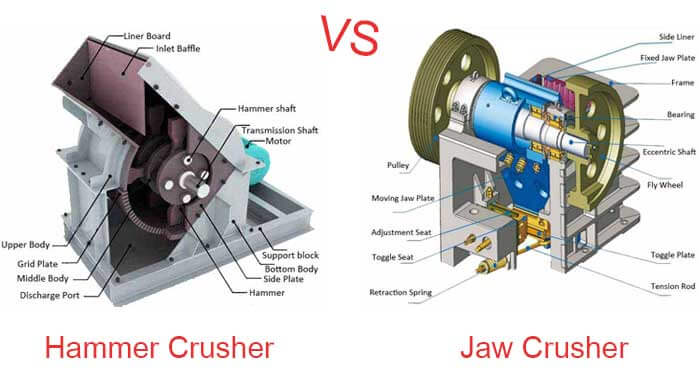

DIFFERENT BETWEEN HAMMER CRUSHER ROTOR AND IMPACT CRUSHER ROTOR

1. Inside the impact crusher rotor, the crusher rotor runs clockwise, and the plate hammer faces the material from bottom to top, while inside the crusher, the crusher rotor runs counterclockwise, and the hammer head strikes in the direction in which the material falls.

2. The plate hammer of the impact crusher is firmly fixed on the crusher rotor by a mechanical clamping structure, and has a large moment of inertia when rotating with the rotor. Compared with the hammer crusher (the hammer head is suspended), the rotor of the impact crusher has greater momentum, which is suitable for crushing harder materials and consumes less energy.

3. The hammer head of Impact crusher is rigidly connected with the crusher rotor, which has a milling effect before the material is discharged; while the hammer head of the hammer crusher hangs freely on the crusher rotor. When encountering materials that are difficult to crush, it must be turned to avoid it Protect the hammer from damage, but not break.